GFRC Concrete: What is it and How to Make

If you haven’t already heard of glass fiber reinforced concrete (GFRC), then you are in for a treat.

A very specialised type of concrete that combines cement-based composite material and alkali-resistant glass fibers, GFRC can be used for a whole host of applications due to its resilient but lightweight structure.

Interested to know more about glass fiber reinforced concrete, what it can be used for and how to make it?

Within the below guide, you’ll discover:

- What is GFRC concrete?

- What are the components of GFRC concrete

- GFRC mix designs

- A step-by-step guide on how to make GFRC concrete

- What can GFRC concrete be used for?

Ready to get started?

In just five minutes, you will know everything there is to know about GFRC concrete and its many benefits.

WHAT IS GFRC CONCRETE?

GFRC stands for glass fiber reinforced concrete and is a composite that is made up of a combination of cement, fine sand, a polymer, water, and other admixtures.

It is similar to chopped fiberglass which is used to form boat hulls and other more complex shapes, although GFRC is not as strong.

It was first created in the 1940s in Russia, but it wasn’t until the 1970s that it became popular in the mainstream.

There are many benefits to using GFRC, including:

- It can be used to construct lightweight panels as it can be made thinner and lighter than traditional concrete

- It has a high tensile strength

- It is more flexible than traditional concrete

- It is resistant to cracking

- It is extremely durable and can outlive steel-reinforced concrete

- It requires very little maintenance

- It is resistant to climate changes and fires

- It is cost-effective

WHAT ARE THE COMPONENTS OF GFRC CONCRETE?

To better understand what GFRC is and what it can be used for, it can be helpful to find out what this type of concrete is made up of.

1. CEMENT

Portland cement is the most commonly used cement for making GFRC concrete. It is available in white and grey. Grey Portland cement should be avoided if you want to add colour as the dark grey pigment is hard to overcome. Overall, white cement is the better option, but it is more expensive than grey.

2. SILICA SAND

Silica sand, often referred to as industrial sand, is the perfect type of sand for GFRC concrete as it helps to prevent blockages and delivers less abrasion to the equipment. It is worth noting that this type of sand can be difficult to find, although your local masonry should have some in stock.

Do not use basic playground sand, as this will clog up your equipment.

3. AR GLASS FIBER

AR (alkaline resistant) glass fiber has been used in GFRC concrete for decades due to its durability and alkaline-resistant which is a result of adding zirconia to the glass. These fibers are often used for countertops, fireplace surrounds, and other decorative applications.

AR glass fiber is available in chopped strands, in a ball of twine known as roving, and as scrim, which is a grid-like pattern that is sold on a roll.

4. WATER

When it comes to how much water to add to GFRC concrete, the less water you use, the stronger the concrete. Typically, spray-up GFRC has a low water-cement ratio. The water you use should be free from contaminants and as clean as possible.

5. FORTON VF-774

Forton VF-774 is an acrylic, co-polymer dispersion that has been specially formulated for GFRC concrete. It is also designed to be able to remain stable and durable when combined with the high PH levels of Portland cement.

Other benefits of this key component of GFRC concrete include easy spraying on vertical surfaces, UV stability, and the elimination of spider cracking and crazing.

6. PLASTICISER

A plasticiser is a chemical compound that enables the production of concrete with roughly 15% less water content. You can also find super-plasticisers that reduce the amount of water needed by up to 30%.

Plasticisers are also used to retard the curing of concrete.

7. PIGMENT

Concrete pigment is a dry powder that is used to add colour to GFRC concrete. The more pigment you use, the more intense the colour. Typically, a 5% dosage is added. Pigments are available in a wide range of colours.

GFRC MIX DESIGNS

The GFRC mix design basically refers to the ratio that the components are mixed at. There are two different GFRC mix designs that you can choose from:

1. PREMIX

This is by far the most common GFRC mix design and is suitable for both small and medium-sized users. The premix process involves spraying through a hopper gun, with the back mix added by hand.

Premix is a much cheaper option than spray-up, although a special spray gun and pump are needed. However, fiber orientation is more random, and the fibers are shorter, which results in less strength.

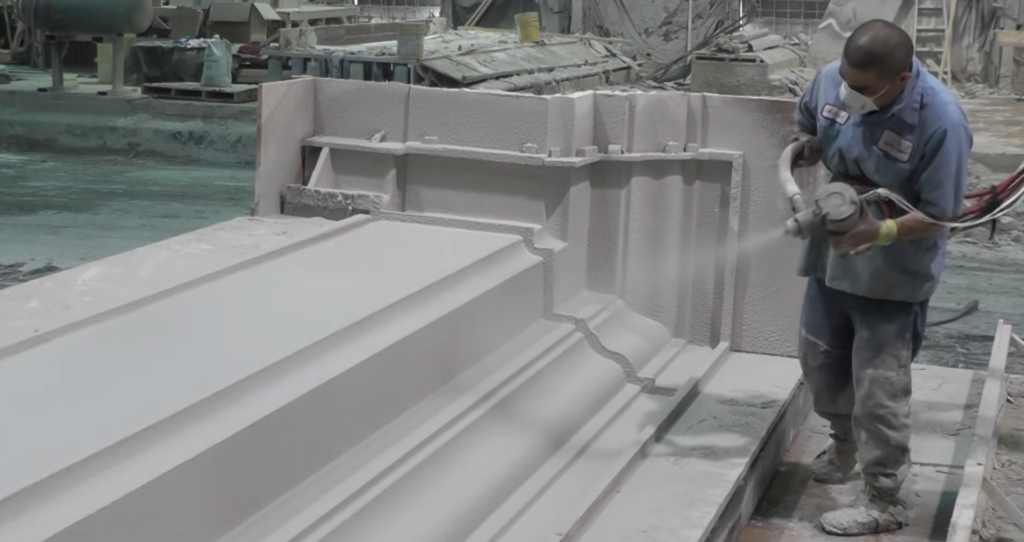

2. SPRAY UP

This GFRC mix design process is far less common and is mostly used by high-end producers who use large volume spray equipment. The spray-up process is typically used for very large architectural panels and provides a higher glass percentage.

On the plus side, spray-up allows for very high fiber loads using long fibers, which results in the greatest possible strength and durability. However, the specialised equipment needed is expensive, typically over $20,000.

HOW TO MAKE GFRC

The process of making GFRC concrete is simple but must be followed in the correct order to avoid a lumpy end product. You can make GFRC concrete in a standard concrete mixer but for optimum results, opt for a high shear mixer that has been specifically designed to make GFRC concrete.

If you want to know how to make GFRC concrete or how to make GFRC panels, follow the below steps:

- Weigh or batch all materials

- Add all the liquids, including the Forton VF-774 and 2oz of plasticiser, to the mixer

- Start the mixer on slow – 300-500 rpm

- Add pigment if colour is desired

- Add the silica sand

- Add the Portland cement and increase the mixer speed to high – 1,000-1,800 rpm

- Mix on high for 1-2 minutes

- Add the remaining plasticiser to achieve the desired consistency

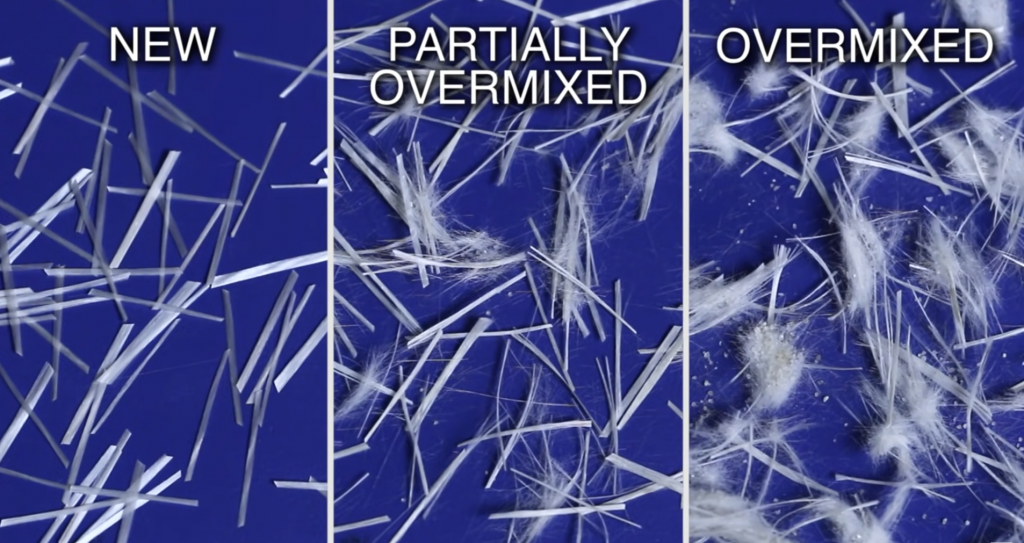

- Reduce the mixer speed to slow and gradually add the Premix fiber until fully dispersed

Once you have added the fiber, you must not mix for too long or at too high a speed as this can damage the fiber, resulting in placement issues and/or reduced strength.

CASTING, SPRAYING & CURING GFRC

CASTING

For casting GFRC concrete, pour the mixture into a single spot at the lowest point of the mould and allow the mixture to seek its level. After casting, consolidate the slurry and remove any entrapped air using either a hand vibrator or vibrating table.

SPRAYING

Spraying can be used for both higher volume smaller parts and lower volume applications.

For higher volume – GFRC slurry can be sprayed into molds using rotor/stator or peristaltic pumps that are specifically designed for GFRC. Whichever spray pump you use, a face coat without fiber is typically applied first. Once this has stiffened, a fiber backup mix is applied in multiple passes, with compaction between each pass.

For lower volume – A hopper gun can be used to apply face mix, and then the GFRC backup mix is applied by hand.

CURING

After placement, you should cover GFRC concrete with a plastic tarp or sheeting to prevent moisture loss and to maintain the heat of hydration. Allow the concrete to cure in the mold for between 12-16 hours. Curing temperatures should be maintained above 50°F/10°C in order to ensure proper film-forming of the Forton VF-774.

WHAT IS GFRC USED FOR?

GFRC concrete is used in the below construction works:

- Building renovations

- Water and drainage works

- Bridge and tunnel lining panels

- Permanent formwork method of construction

- Architectural cladding

- Acoustic barriers and screens

It is most commonly used in exterior cladding. However, due to its strength, flexibility, and chemical properties, GFRC can be used for a wide range of applications.

As it can take the form of pretty much any shape or size, GFRC concrete can be found in architectural features such as moldings and landscapes. It can also be used for modular buildings, as well as walls, roofs, floors, and foundations.

In the engineering sector, GFRC is used to construct bridges, tunnels, and drainage.

It is also used as ornamental concrete to create items such as fountains, statues, domes, and planters.

Most recently, decorative concrete artisans have started to use GFRC concrete to create decorative panels such as fireplaces, countertops, and artificial rock work.

CONCLUSION

Glass fiber reinforced concrete is lighter, faster, and stronger than traditional precast concrete.

It can be used to create almost anything that traditional concrete can, and it has the added benefit of more aesthetic options for users.

Whether you opt for the spray-up option, which uses a liquid concrete mix that sprays glass fibers, or you go for a premix in which the liquid concrete is poured into molds, glass fiber reinforced concrete is suitable for a variety of different projects and guarantees a superior finish.

For more concrete and casting materials check out our product range.